Ready Mix Concrete London offers a versatile solution for C10 concrete mix, which is widely used in construction projects. We aim to empower your construction ideas with a premium quality concrete mix that makes your buildings enduring.

We are dedicated to providing top-quality C10 concrete mix to ensure quality and consistency in every batch. These are the cornerstones of our service. Our team of experts not only adds unique value to your project but also comprehends the importance of quality, reliability, and efficiency for domestic purposes. Our C10 concrete mix ensures the necessary attributes for successful foundational work, paving, or other non-structural projects.

Catering to every concrete requirement of your construction projects, we cover a range of concrete solutions:

Our agile and on-schedule concrete delivery services ensure a smooth workflow and timely completion of your project.

From small domestic projects to commercial skyscrapers, our efficient and versatile concrete pumps can handle them all.

Designed to withstand extraordinary damping and humidity, we are offering waterproof concrete for versatile applications.

Based on your concrete requirement, our on-site mix concrete services are designed for long-distance deliveries.

To denote the strength class of a particular mixture, we use C as a parameter. C10 concrete mainly refers to the strength of concrete, which is 10 N/mm² at 28 days. It has a mix ratio of 1:3:6.

You can use C10 concrete mix in various applications because of its efficiency and flexibility.

Domestic Concrete Foundations: Domestic concrete foundations are not too deep or wide, and they do not require greater strength. This makes our C10 the finest choice for these kinds of purposes.

Flooring: The C10 mix is suitable for flooring as it goes over the subflooring and foundation without requiring much strength.

Filling: C10 concrete is used for filling purposes because of its good workability. Its low strength and flexibility make it suitable for a few structural works, such as filling.

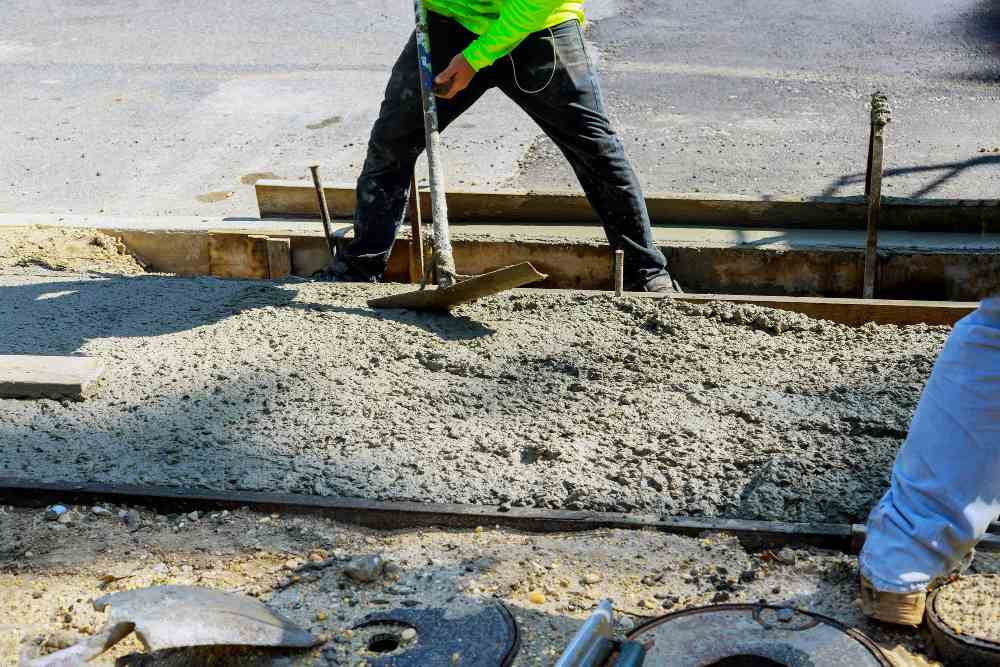

Drainage Works: C10 concrete is the preferred mixture for drainage work to create channels that direct water runoff away from structures and paved areas.

Shallow Foundations: C10 mix is often used to fill shallow foundations, which eliminates the need for brick.

C10 concrete is also used for blinding house floors, non-aggressive ground conditions, cavity fill, mass fill, kerbing, and haunching.

Looking for a concrete supplier in London? Contact our experts to discuss your requirements and witness unmatched concrete delivery services.

Don’t hesitate to contact us regarding any queries about the C10 concrete mix. You can reach out to us via phone (0207 4584543) or email (info@readymixconcretelondon.co.uk), and we will help you with the best concrete solutions, as customer satisfaction is our top priority.

C10 concrete (Gen 1 concrete) is an incredibly flexible mix usually used for buildings or houses, including unreinforced strips, patio slabs, pathways, trench fill, and agricultural work.

Driveway requires more strength to withstand the weight of vehicles, so you should not use C10 concrete. To prevent cracks and deterioration, it is recommended that a higher-strength concrete mix, such as C20, C25, or C30, be used.

The C10 concrete mix ratio can be adjusted as per your requirements, but it is recommended to do this carefully. The ratio limits the amounts of cement, sand, aggregate, and water, which directly affect the strength of the material.

C10 concrete mix depends on several factors, such as temperature, stickiness, and design. Nevertheless, it takes some hours after you have made a mixture.

There are multiple requirements for a concrete mix design:

A boom pump uses a robotic arm (boom) to deliver concrete with precision at height or distance, making it ideal for large-scale and high-rise projects. A line pump, on the other hand, is better suited for smaller, ground-level jobs and uses flexible hoses to deliver concrete. We offer both types depending on your project requirements.

With a boom pump, concrete can be pumped up to 70 metres vertically and over 200 metres horizontally. Line pumps can reach around 150 metres horizontally, depending on the setup and hose diameter. Our experts will assess your site and recommend the best solution to reach even the most challenging locations.

Yes, it’s important to ensure the site is accessible, level, and free from obstructions. There should be enough space for the pump vehicle to park and operate safely. If you’re unsure about access or clearance, our team can provide advice or arrange a pre-site visit.

The duration of a concrete pumping job depends on the volume and complexity of the pour. In general, a typical residential pour can be completed in under two hours. Our efficient service aims to minimise downtime and keep your construction project on schedule.

Yes, concrete pumps can operate in light rain and mild weather conditions, but heavy rain, high winds, or frozen ground may delay or halt operations for safety reasons. We always monitor the forecast and keep you informed of any possible schedule changes.

Yes, all our pump hires include a trained and experienced operator who will handle the equipment and ensure concrete is placed efficiently and safely. They’ll also help guide you through the process on-site, ensuring a smooth pour every time.

Ready Mix Concrete London (Trading as Pro-Mix Concrete Ltd)

Copyright © 2025 | Ready Mix Concrete London (Trading as Pro-Mix Concrete Ltd) | All Rights Reserved.